Krasnogvardeisky Machine-building Plant that manufactures forced draft units (units providing forced displacement of air and flue gas in the process systems) works with customers from various industries: metallurgical, chemical, construction and power industries. And each one of them requires its specific engineering solutions. When a forced draft unit is created for a specific task, it is necessary to take into account factors such as dimensions of the unit, its efficiency, generated noise, engine power, weight, fan rotation speed, price, operating cost and service life.

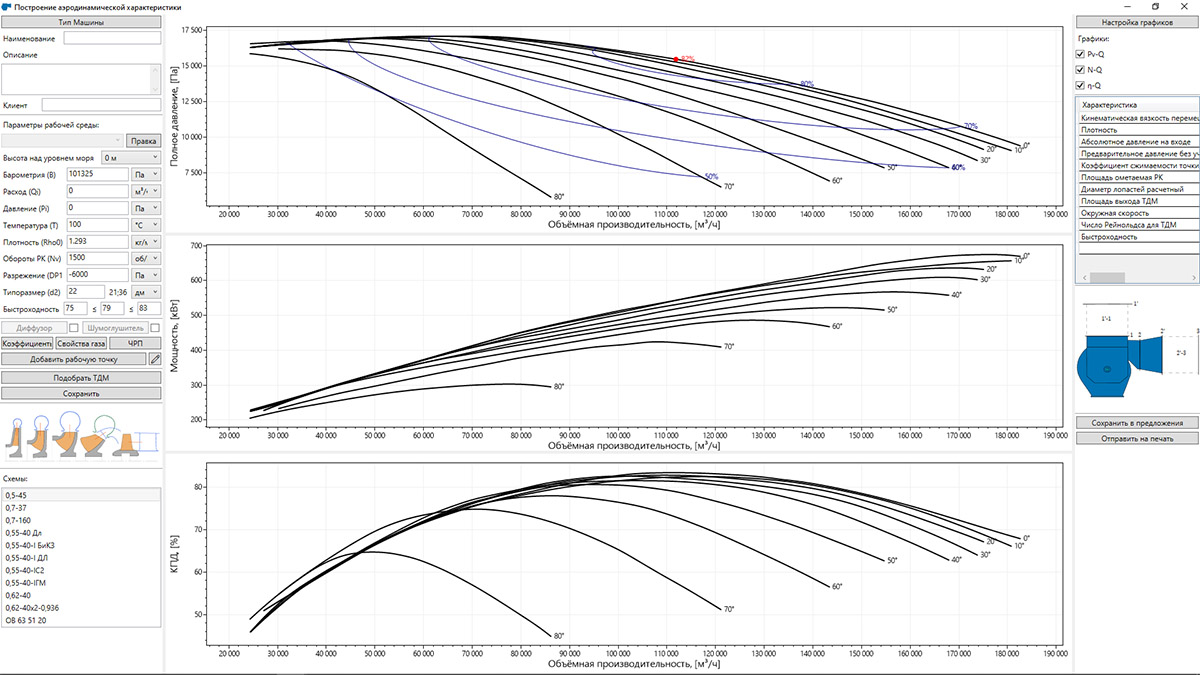

For the selection process to be faster and easier, MST company has developed a software package for the company enabling it to plot the precise characteristics of the forced draft unit, to determine its cost, the necessary materials, etc. This made the drafting of the commercial offers easier and enabled to keep a base of ready-made solutions.

Basically, MST has created a complete model of the forced draft unit with over 50 parameters, where each parameter has its own set of characteristics. Besides, large research has been carried out to create a design calculations library which included a large set of references regarding the aerodynamic characteristics, noise characteristics, inertial characteristics, range of products, electric motors, outline drawings, templates of documents, calculations of node weight. This helps to select a forced draft unit that is the most suitable for the customer.

In addition to the standard functionality for forced draft unit design calculation, another functionality, namely the diagrams editing, available to the administrators only, was added. Now, they have the option enabling to manipulate the display (what to display and what not to display), and to adjust the curves using the mouse, instead of manually inputting the values, as in the previous system.

MST and KMZ are planning to significantly extend the functionality of the software package, and, basically, to transit to a unique production ERP platform. The creation of a tool that, after forced draft unit design calculation, will reserve the time of the CNC machines for their production, is already in progress.